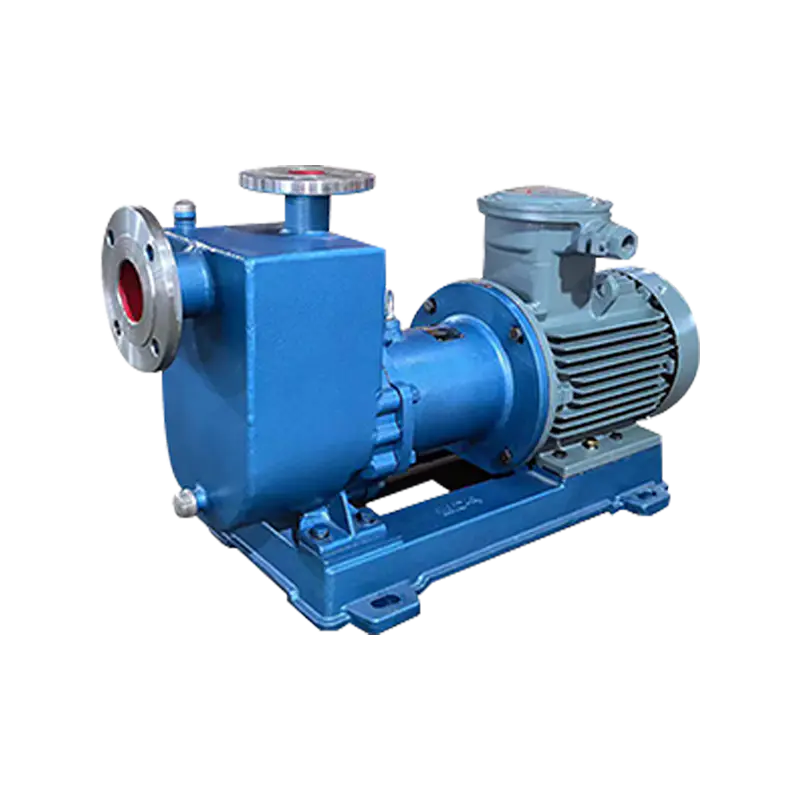

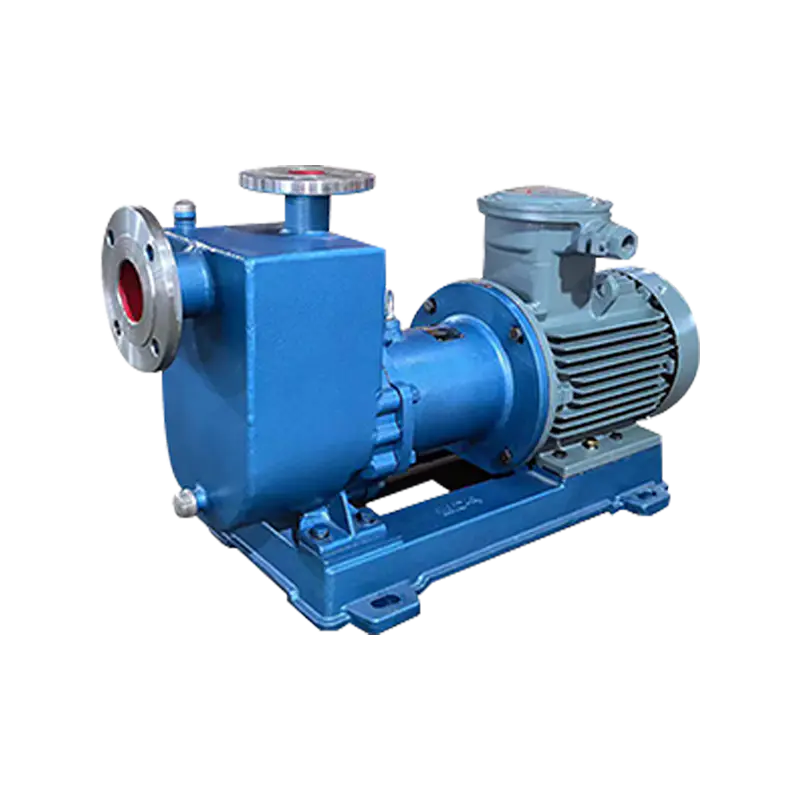

In the world of industrial and commercial fluid transfer, efficiency, reliability, and durability are non-negotiable. Among the many tools designed to meet these demands, the stainless steel self-priming pump stands out as an indispensable workhorse. Whether you’re managing water treatment systems, chemical processing plants, or agricultural irrigation setups, this pump has carved its niche by offering unmatched performance in challenging environments.

At its core, a self-priming pump is engineered to operate without the need for manual priming—a feature that sets it apart from traditional pumps. This ability to evacuate air and create a vacuum allows it to draw liquid into the system autonomously, even when the pump isn’t initially filled with fluid. For industries where time is money, this translates into significant savings and smoother operations.

What makes stainless steel self-priming pumps particularly remarkable is their material composition. Stainless steel is renowned for its resistance to corrosion, heat, and chemical damage. When handling aggressive fluids such as acids, alkalis, or saline solutions, these pumps maintain their structural integrity and performance over extended periods. This resilience not only reduces maintenance costs but also minimizes downtime, ensuring continuous productivity.

Beyond their robustness, stainless steel self-priming pumps are versatile. They can be deployed in a wide range of applications, from dewatering construction sites to transferring food-grade liquids in hygienic environments. Their adaptability stems from the fact that they can handle both clear liquids and those containing solids or debris, making them ideal for wastewater management and slurry transport.

Another advantage lies in their design simplicity. Unlike some specialized equipment that requires extensive training to operate, these pumps are relatively straightforward to install and maintain. With fewer moving parts compared to other types of pumps, wear and tear are minimized, further enhancing their longevity. Additionally, modern innovations have led to energy-efficient models, allowing businesses to reduce their carbon footprint while cutting operational expenses.

But perhaps the most compelling reason to consider stainless steel self-priming pumps is their role in safeguarding human health and environmental well-being. In sectors like pharmaceuticals and food production, hygiene is paramount. The smooth, non-porous surface of stainless steel prevents bacterial growth and contamination, ensuring the purity of the transferred substances. Similarly, in wastewater treatment facilities, these pumps play a critical part in preventing pollution by efficiently managing effluents.

Despite their numerous advantages, selecting the right pump requires careful consideration. Factors such as flow rate, pressure requirements, and the nature of the fluid being handled must all be taken into account. Consulting with experts who understand your specific needs can help ensure you choose a model tailored to your application.